Modern industries rely on complex mechanical systems to power operations, maintain efficiency, and ensure sustainability. Among these are water turbines, turbine service units, fans, and compressors, which play vital roles in energy production, manufacturing, and industrial processes. Additionally, the growing emphasis on specialized training for turbine systems highlights the importance of developing skilled professionals. This article explores the significance of these components and the value of training programs in their operation and maintenance.

Water Turbines: Driving Renewable Energy Solutions

A Water turbine is a mechanical device that transforms the energy of flowing or falling water into mechanical energy, which is often converted into electricity. These turbines are at the core of hydropower plants, offering a sustainable alternative to fossil fuels. Their ability to harness renewable energy makes them integral to global efforts to reduce carbon emissions.

Water turbines come in various designs, including Francis, Pelton, and Kaplan turbines, each suited to specific conditions such as water flow and head. Regular maintenance and precise engineering are critical for maximizing their efficiency and ensuring their long-term reliability in energy production.

Turbine Service Units: Ensuring Reliability and Longevity

A turbine service unit is essential for maintaining the performance of turbines used in energy production and industrial operations. Over time, turbines experience wear and tear due to continuous operation, high stress, and exposure to environmental factors. Service units are equipped with advanced tools and diagnostic equipment to identify and address issues, ensuring that turbines operate efficiently.

These units handle tasks such as blade inspections, thermal coating repairs, and balancing tests. By proactively maintaining turbines, service units help industries avoid costly downtime and optimize energy production, contributing to overall operational success.

Fans and Compressors: Industrial Workhorses

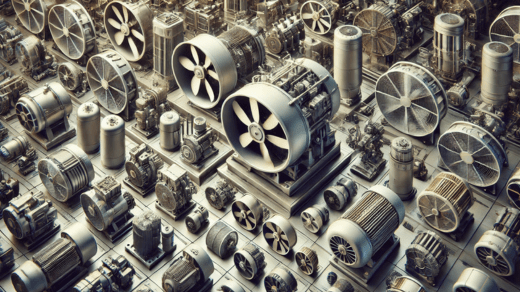

Fans and compressors are indispensable in industrial processes, providing crucial support in ventilation, cooling, and gas compression. Fans are primarily used for moving air or gases in systems like HVAC, exhaust, and cooling setups. Compressors, on the other hand, increase the pressure of gases, enabling their use in refrigeration, pneumatic tools, and industrial processes.

Both fans and compressors require routine maintenance to ensure they function efficiently. Neglecting their upkeep can lead to reduced performance, increased energy consumption, and equipment failure. Proper maintenance schedules and inspections are vital for prolonging their operational lifespan and maintaining industrial productivity.

Training Turbines: Building Expertise in the Workforce

The rapid evolution of turbine technology has made ttraining turbines a critical part of workforce development. Training programs are designed to equip technicians and engineers with the skills required to operate, maintain, and troubleshoot turbine systems effectively.

These programs often incorporate hands-on training with simulators and real-world equipment, ensuring participants gain practical knowledge. Training focuses on areas such as turbine design, system operations, safety protocols, and performance optimization. As the demand for skilled professionals grows, training initiatives ensure that industries are prepared to meet the challenges of modern turbine technologies.

Conclusion

Water turbines, turbine service units, fans, and compressors are indispensable in energy production and industrial processes. Their proper operation and maintenance are crucial for efficiency, sustainability, and productivity. Additionally, training turbines and related systems empower professionals to excel in managing these technologies. By investing in these critical components and workforce development, industries can drive innovation, ensure reliability, and support a greener, more sustainable future.