Stainless steel decorative profiles have become a pivotal element in modern design and architecture. Known for their durability, aesthetic appeal, and versatility, these profiles are extensively used in various applications ranging from residential to commercial spaces. This guide explores the world of stainless steel decorative profiles, covering everything from their types and applications to maintenance tips and future trends.

Stainless steel decorative profiles are sleek, modern elements used to enhance the aesthetic and functional aspects of various spaces. They come in numerous shapes and sizes, including U-profiles, T-profiles, L-profiles, and more, each serving specific design purposes.

Importance and Relevance in Modern Design

In contemporary architecture and interior design, stainless steel profiles are valued for their clean lines, reflective surfaces, and ability to complement a variety of materials such as glass, wood, and stone. Their importance is highlighted in both structural and decorative roles, making them a staple in modern design projects.

Types of Stainless Steel Decorative Profiles

U-Profiles

U-profiles are widely used for their structural support and aesthetic enhancement in both horizontal and vertical applications.

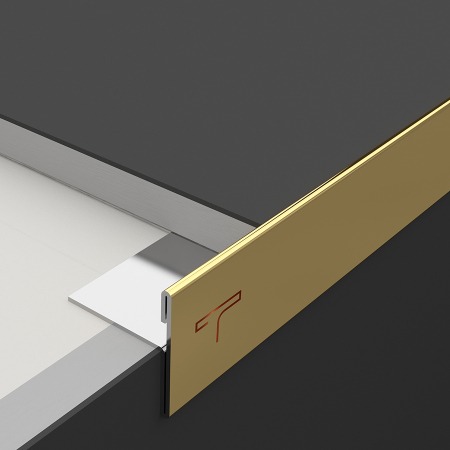

T-Profiles

T-profiles provide a unique design element and are often used in flooring transitions and paneling systems.

L-Profiles

L-profiles, also known as angle profiles, are versatile and commonly used for edge protection and framing.

Flat Profiles

Flat profiles offer a minimalist look and are perfect for surface trims and decorative inlays.

Custom Profiles

Custom profiles are designed to meet specific project requirements, allowing for unique shapes and finishes tailored to individual design needs.

Materials and Grades

Common Stainless Steel Grades (304, 316, etc.)

The most common grades of stainless steel used in decorative profiles are 304 and 316, known for their excellent corrosion resistance and mechanical properties. Grade 304 is the most versatile, while grade 316 offers superior resistance to chloride environments.

Material Properties and Benefits

Stainless steel is chosen for its high strength, durability, and resistance to corrosion and staining. These properties make it ideal for both indoor and outdoor applications.

Manufacturing Process

Cold Rolling

Cold rolling is a process where the steel is rolled at room temperature, resulting in a smooth finish and precise dimensions.

Hot Rolling

Hot rolling involves rolling the steel at high temperatures, making it easier to shape and form.

Extrusion

Extrusion is used to create complex profile shapes by pushing the material through a die.

Finishing Techniques

Finishing techniques such as brushing, polishing, and coating are applied to enhance the visual appeal and surface quality of the profiles.

Applications

Residential Applications

In homes, stainless steel profiles are used in kitchens, bathrooms, and living spaces for features like countertops, backsplashes, and trim.

Commercial Applications

Commercial spaces such as offices, hotels, and retail stores use these profiles for a modern and professional look.

Industrial Applications

In industrial settings, stainless steel profiles provide durability and hygiene in environments like food processing plants and laboratories.

Benefits of Stainless Steel Decorative Profiles

Durability and Longevity

Stainless steel profiles are known for their long lifespan and resistance to wear and tear.

Aesthetic Appeal

Their sleek and modern look enhances the visual appeal of any space.

Resistance to Corrosion and Staining

Stainless steel is highly resistant to corrosion and staining, making it ideal for various environments.

Ease of Maintenance

These profiles are easy to clean and maintain, requiring minimal upkeep.

Design and Customization

Standard vs. Custom Designs

While standard profiles are readily available, custom designs offer unique solutions for specific project needs.

Popular Finishes (Brushed, Mirror, Satin)

Finishes such as brushed, mirror, and satin are popular for their distinct visual effects and functional benefits.

Customization Options

Custom profiles can be tailored in terms of shape, size, and finish to meet precise design specifications.

Installation and Maintenance

Installation Guidelines

Proper installation ensures the longevity and performance of stainless steel profiles. This includes correct measurements, alignment, and securing methods.

Maintenance Tips for Longevity

Regular cleaning with non-abrasive cleaners and periodic inspections help maintain the profiles’ appearance and integrity.

Comparative Analysis

Stainless Steel vs. Aluminum Profiles

Stainless steel profiles offer superior strength and corrosion resistance compared to aluminum.

Stainless Steel vs. Plastic Profiles

While plastic profiles are lightweight and cost-effective, stainless steel provides unmatched durability and aesthetic value.

Challenges and Solutions

Common Challenges in Use and Installation

Challenges such as fitting precision and material compatibility can arise during installation.

Solutions and Best Practices

Using professional installation services and adhering to manufacturer guidelines can mitigate these challenges.

Future Trends

Emerging Trends in Design

Trends such as the use of mixed materials and sustainable designs are gaining popularity.

Technological Innovations

Advancements in manufacturing technologies are enabling the creation of more intricate and durable profiles.

Expert Insights

Quotes from Industry Professionals

Experts emphasize the importance of choosing the right material and finish for specific applications.

Case Studies

Case studies highlight successful projects where stainless steel profiles have significantly enhanced design and functionality.

Environmental Impact

Sustainability and Recycling

Stainless steel is a recyclable material, making it an eco-friendly choice for sustainable projects.

Eco-Friendly Practices

Manufacturers are adopting eco-friendly practices to reduce the environmental impact of production.

Summary of Key Points

SS decorative profile offer a blend of durability, aesthetics, and versatility, making them ideal for various applications.

Future Outlook

The future of stainless steel profiles looks promising with ongoing innovations and an increasing emphasis on sustainability.